What is the difference between a PTC Contact Heating Element and a PTC Cartridge Heater?

In PTC Contact Heaters, the PTC ceramic is press-fitted into an aluminum profile for optimal power output. In PTC Cartridge Heaters, the PTC ceramic is enclosed in a silicone jacket which allows for smaller and circular designs.

What is the surface temperature of a PTC Contact Heating Element?

The maximum surface temperature of PTC Heating Elements can be specified within a range of approx. 60°C to max. 240°C.

Is it possible to operate PTC Heating Elements / PTC Cartridge Heaters without an additional temperature fuse?

Yes. Due to the PTC effect, the heating element limits itself to the specified temperature, there is no danger of overheating.

How can I keep my component at temperature using a PTC Heating Element without separate control?

With the correct design of the PTC heating element, the desired temperature in the application is achieved without additional control.

Can I operate a PTC Contact Heater at a wide voltage range and what are the consequences?

Yes, PTC heaters are multi-voltage capable and can be operated at 100 - 240 V with almost the same power. This is a great advantage over conventional heating elements.

Why is it not possible to calculate the exact power output of a PTC Contact Heating Element?

As PTC Heating Elements are dynamic heating elements, their performance strongly depends on the application conditions. The correct design of the heating element is crucial which is why our engineers always design a heater based on the input of the customer.

Which factors must be considered when connecting a PTC Contact Heater?

PTC heaters experience an increased inrush current for a few seconds each time they are switched on. We therefore recommend to use a time-delay fuse in order to protect the application.

What are typical applications of PTC Contact Heating Elements?

They can be used for all applications that require heating of components or housings with high efficiency but limited space. Due to their protection class II design, PTC contact heating elements are also suited for safety-relevant applications.

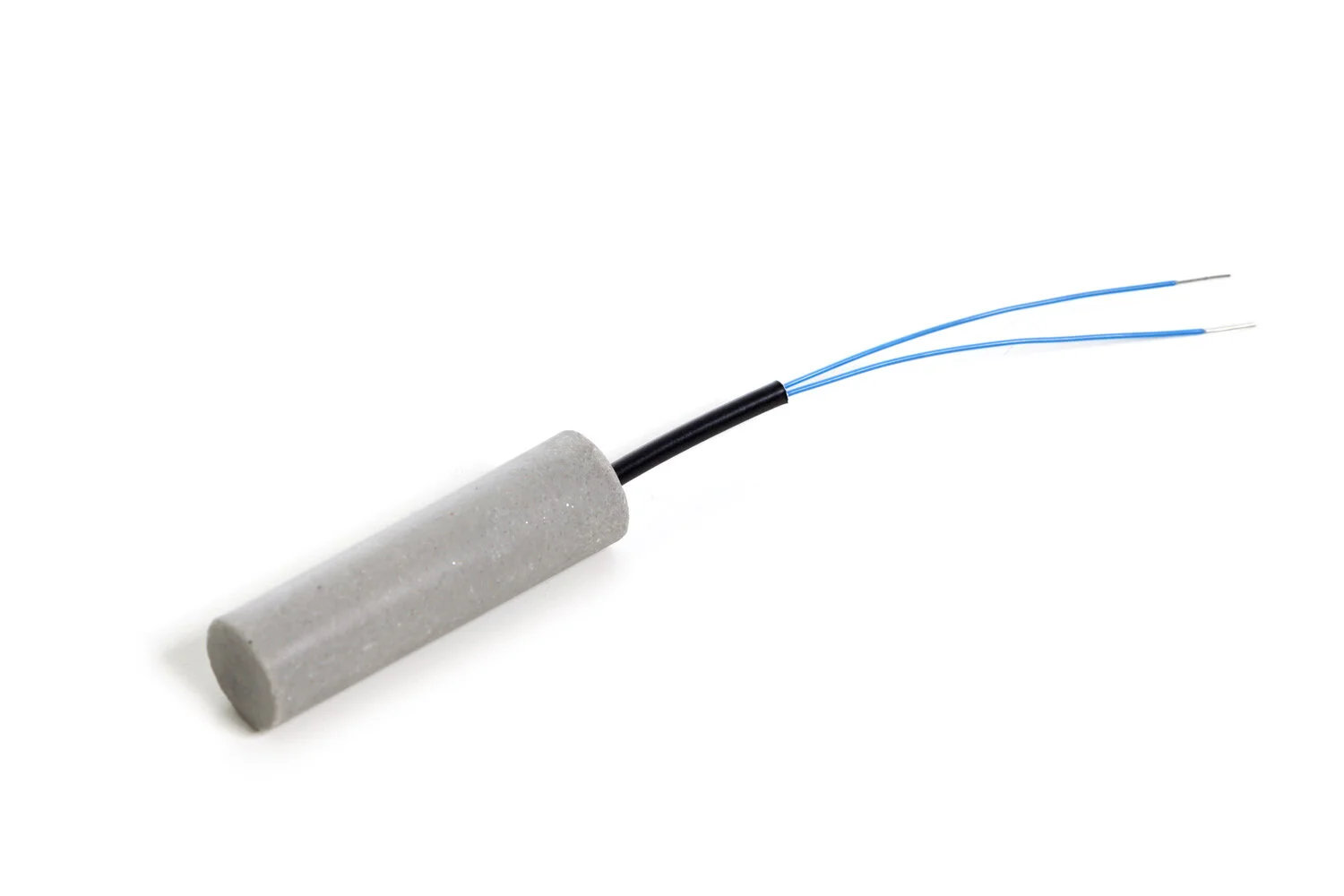

What are typical applications of PTC Cartridge Heaters?

PTC Cartridge Heaters are used for very low power and low temperature applications. Their high flexibility in shape makes them suitable for most difficult space conditions.